ANODIZING PLANTS

From its early days, making anodizing plants has always been the core business at Cisart, from the simple manual ones of the early 70s of the past century, to the sophisticated automated ones supplied nowadays.

All plants are made according to specific directives: AASTM, BS and QUALANOD for Architectural profiles, Boeing and Airbus for the Aviation industry and main car makers specifications for Automotive.

Depending on which material needs treatment and on its end use, several configurations are available:

Horizontal anodizing, mainly for standars lenght extrusions and cut to size parts

Horizontal Anodizing plant is fully automated for aluminium profiles, featuring 4 X 15000A anodizing and 2 electrocolouring tanks, an automated chemicals dosage system, fumes suction and scrubbing equipment.

Anodizing plant for high range automotive components

Automated horizontal anodizing plant for high range automotive components, including 5 anodizing tanks, of which one for hard coats, several colouring tanks and complete with fumes suction and scrubbing equipment.

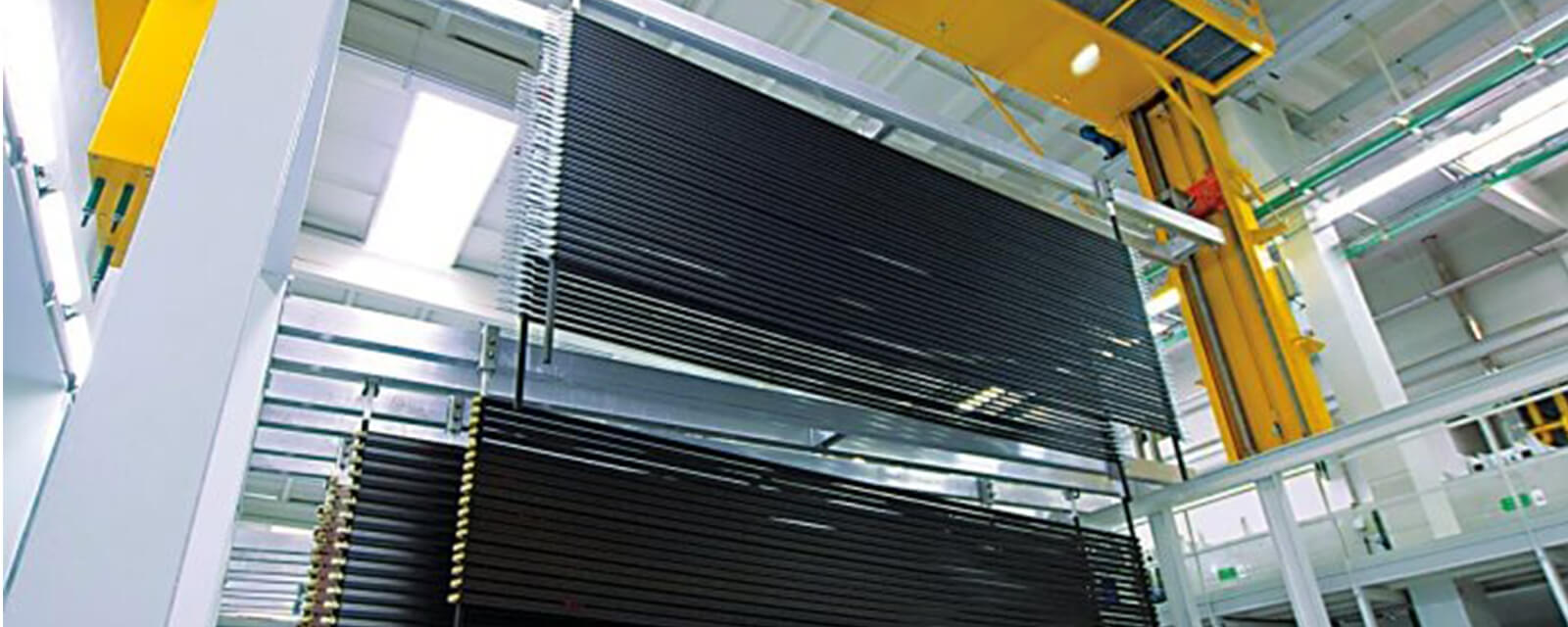

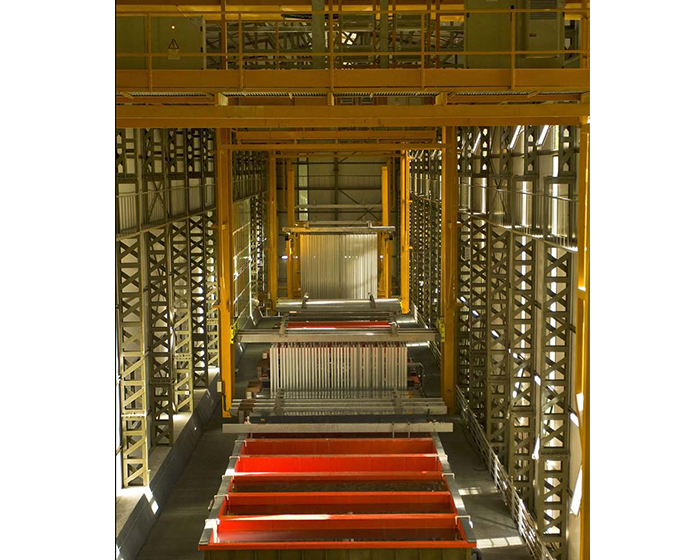

Highly productive vertical anodizing, specific for standard lenght profiles

This unique vertical anodizing plant extending over two floors, provides quality anodizing for architectural use as well as flash anodizing as a pretreatment for further online powder application. The 180.000A plant features four anodizing tanks and two electrocolouring ones. Alternative conventional chrome conversion available online also.

Continuos coil anodizing

In the anodizing plant illustrated above, untreated coil anodizing is a whole colpete sector where Cisart has lot of experience from a few inches to eight feet wide are unwound through a number of closed reaction tanks where the process itself takes place and then rewound back into coils upon completion. All parameters of the main reactions taking place at variable speeds are set and monitored by the system’s automation centre.