ELECTROPHORETIC COATING

Hard anodizing is in demand in sensitive industries such as automotive and food, Unlike spray application, one of the main advantages of electrophoretic painting is to cover all exposed surfaces, even the most hidden ones, with a durable coat of paint.

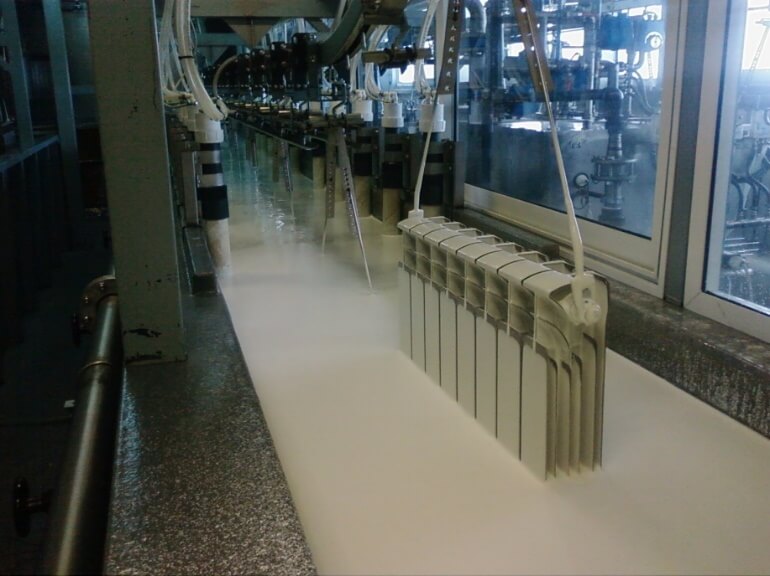

Main application is in the automotive industry. Finds also application in the application of a first coat of protective paint followed by a second coat of powder paint in the manufacturing of aluminium heating radiators.

COMPLETE ELECTROPHORETIC PAINTING PLANT FOR ALUMINIUM RADIATORS CAPABLE OF TREATING UP TO 7.500.000 PIECES/YEAR WITH CONTINUOUS ONLINE PRETREATMENT AND FINAL POWDER APPLICATION ON VISIBLE SURFACES

HORIZONTAL PAINTING LINE WITH QUICK COLOUR CHANGE AND FAST CLEANING BOOTHS FOR POWDER APPLICATION ON ALUMINIUM AND STEEL, FEATURING A VARIABLE SPEED BIRAIL POWER AND FREE CONVEYOR, AN INTEGRATED TUNNEL PRETREATMENT LINE AND AN ENERGY SAVING CURING OVEN

POWDER & LIQUID PAINTING

Cisart proudly supplies both liquid and powder spray coating plants for aluminium and steel, inclusive of the associated online or offline pretreatment section as requested.

Sensitive items such as spraying guns, booths and conveyors are from major international suppliers, while all the rest is engineered and manufactured within Cisart’s facilities.